DGXPRESS ER-641 / ER-642

Eco-solvent Printer

High Speed Printing

DGXPRESS is the ideal solution for those who need professional, reliable equipment which can exceed the demands of a thriving economy. Every element of the DGXPRESS eco-solvent printing solution is meticulously refined to deliver high-speed output with healthy margins.

The newly developed high-speed data control technology maximizes the performance of the print heads achieving high-resolution output with fewer passes. With the two-pass print set-up of the ER-642, you can achieve speeds up to 76.1 m2/h.

Exceptional Quality

Devices in the DGXPRESS range have been precision- engineered to produce prints at high speeds without compromising on print quality.

Features such as VersaWorks’ True Rich Color ensure the reproduction of vivid and accurate colors, even with only CMYK inks.

Professional and Fast Digital Print

With enhanced speed and Roland DG quality, you can produce a huge range of print products in record times.

High Performance Ink

Using the latest D-EA2 inks for high-performance and economical printing, you can get maximum speed with dual-CMYK. The cartridges are also paper-based to reduce environmental impact.

DGXPRESS ER-642 – High-performance Features

Simple Maintenance

The DGXPRESS ER-642 is designed to make it easy for users to replace parts and consumables. This ensures that downtime is kept to a minimum, even where access to the Roland DG service network is unavailable.

Optional Dryer Unit

In addition to the standard heating system, an extended dryer and blower are available as an option to further accelerate ink drying. Winding up at high printing speeds can also be performed with greater peace of mind.

Integrated Take-up Unit

Robust, accurate and easy to use, the ER-642 is equipped with a take-up unit as standard to enable long unsupervised print runs.

- Adjustable end-cap for various media tube lengths.

- Quick loading with One-touch media holder.

- Compatible with thin films and heavy canvas material.

DGXPRESS ER-641 – Special Features

Low Investment

Achieve a return on your investment faster with the DGXPRESS ER-641. With precision-engineered efficiency and design know-how accumulated over many years, these devices are also a cheap to run, lowering the cost of ownership

Print with Less Downtime

Replace caps, wipers, wiper cleaner, and frushing sponge around the printheads quickly an easily, without the need for a service engineer, resulting in significantly reduced downtime. The nozzle mask function allows you to keep printing even if a nozzle is missing from the head, so your work doesn’t need to stop

Superior Output

Achieve excellent colour reproduction and high-resolution output with fewer passes thanks to a newly developed large print head capable of ejecting finer ink droplets at higher densities

Key Benefits

Affordable and powerful, these products can generate profits and pay for themselves quickly

Produce your work, your way with flexible job-management features.

Plug in and start working immediately thanks to Roland DG’s user-friendly interface.

Track ink usage and more in real time with the Roland DG Connect mobile app.

Access Roland DG’s library of ICC profiles and find hundreds of profiles to match your needs.

VersaWorks 7

Multifunctional RIP Suite

Besides its high-speed RIP functionality, VersaWorks 7 RIP includes a wide selection of productivity-boosting features:

- A range of built-in colour-matching functions including colour charts, finders and multi-device colour calibration.

- New printing modes contain a newly-developed dither pattern that enhances the power of the ER series.

- The Job Variation setting quickly identifies the best print settings for your customers’ needs

Roland DG Connect App

For Everything Creative

Roland DG Connect now offers a more comprehensive suite of tools designed to maximise value and drive business growth. The enhanced platform provides services and resources that enable you to optimise output, connect with a community of professionals, access support, explore new opportunities and much more.

*Some functions are not available with D-EA2 ink

| Printing method | Piezo ink-jet method | ||||||

| Media | Width | 10.2 to 64 in. (259 to 1,625 mm) | |||||

| Thickness | Max. 39.3 mil (1.0 mm) with liner | ||||||

| Roll outer diameter | Max. 9.8 in. (250 mm) | ||||||

| Roll weight | Max. 99 lb. (45 kg) | ||||||

| Core diameter | 3 in. (76.2 mm) or 2 in. (50.8 mm) | ||||||

| Printing width 1 | Max. 63.5 in. (1,615 mm) | ||||||

| Ink | Type | Eco-Solvent Ink (D-EA) 500 ml cartridge | |||||

| Colors | Four colors (Cyan, Magenta, Yellow, and Black) | ||||||

| Printing resolution (dots per inch) | Max. 1,200 dpi | ||||||

| Media heating system 2 | Print heater set temperature: 86 to 113 °F (30 to 45 °C) Dryer set temperature: 86 to 131 °F (30 to 55 °C) | ||||||

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | ||||||

| Power-saving function | Automatic sleep feature | ||||||

| Power requirements | 100-120 / 220-240 Va.c. 50 / 60 Hz 8.9 / 4.5 A | ||||||

| Power consumption | During operation | Approx. 1,180 W | |||||

| Sleep mode | Approx. 50 W | ||||||

| Acoustic noise level | During operation | 66 dB (A) or less | |||||

| During standby | 53 dB (A) or less | ||||||

| Dimensions (width x depth x height) | 113.7 in. x 29.5 in. x 55.8 in. (2,886 mm × 748 mm × 1,415 mm) | ||||||

| Weight | 415 lb. (188 kg) | ||||||

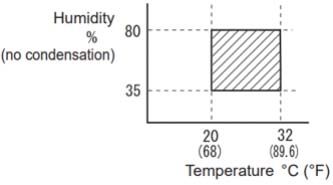

| Environment | During operation 3 | Temperature : 68 to 89.6 °F (20 to 32 °C) , humidity:35 to 80 % RH (no condensation) | |||||

| Not operating | Temperature : 41 to 104 °F (5 to 40 °C) , humidity:20 to 80 % RH (no condensation) | ||||||

| Included items | Dedicated stand, power cord, media take-up unit, media holders, replacement blade for separating knife, cleaning liquid bottle for maintenance, drain bottle, User’s Manual, software (VersaWorks, Roland DG Connect), etc. | ||||||

- Warm-up is required after power up. This may require 5 to 20 minutes, depending on the operating environment.

- Depending on the ambient temperature and media width, the preset temperature may fail to be reached.

DGXPRESS ER-642

| Printing Method | Piezo ink-jet method | |

| Media | Width | 10.2 to 64 in. (259 to 1,625 mm) |

| Thickness | Max. 39.3 mil (1.0 mm) with liner | |

| Roll outer diameter | Max. 9.8 in. (250 mm) | |

| Roll weight | Max. 99 lb. (45 kg) | |

| Core diameter | 3 in. (76.2 mm) or 2 in. (50.8 mm) | |

| Printing width 1 | Max. 63.5 in. (1,615 mm) | |

| Ink | Types | Eco-Solvent Ink (D-EA) 500 ml cartridge |

| Colors | Four colors (Cyan, Magenta, Yellow, and Black) | |

| Printing Resolution (dpi) | Max. 1,200 dpi | |

| Media heating system 2 | Print heater set temperature: 86 to 113 °F (30 to 45 °C) Dryer set temperature: 86 to 131 °F (30 to 55 °C) | |

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | |

| Power-saving Function | Automatic sleep feature | |

| Power Requirements | 100-120 / 220-240 Va.c. 50 / 60 Hz 8.9 / 4.5 A | |

| Power Consumption | During operation | Approx. 1,180 W |

| Sleep mode | Approx. 50 W | |

| Acoustic Noise Level | Print with Vacuum | 66 dB (A) or less |

| During Standby | 53 dB (A) or less | |

| Dimensions (width x depth x height) | 113.7 in. x 29.5 in. x 55.8 in. (2,886 mm × 748 mm × 1,415 mm) | |

| Weight | 415 lb. (188 kg) | |

| Environment | During operation 3 | Temperature : 68 to 89.6 °F (20 to 32 °C) , humidity:35 to 80 % RH (no condensation) |

| Not operating | Temperature : 41 to 104 °F (5 to 40 °C) , humidity:20 to 80 % RH (no condensation) | |

| Included items | Dedicated stand, power cord, media take-up unit, media holders, replacement blade for separating knife, cleaning liquid bottle for maintenance, drain bottle, User’s Manual, software (VersaWorks, Roland DG Connect), etc. | |